- Home

- Brick Making Machine

- Manual brick Making Machine 4 Cavity

Best Quality Block and Brick Making Machines in Guwahati.

“Building Guwahati’s future with reliable bricks”

Lotus Traders is a trusted supplier of Brick Making machines in Guwahati. Choose from our range of cement brick making machines, manual block making machines, and manual concrete brick making machines to meet your construction requirements with ease.

Interlocking Single Cavity Brick Machine

Egg Laying Type Block Making Machine

Semi Automatic Brick/Block Making Machine

Hydraulic Semi Automatic Brick Machine (Dhokla)

Automatic 4 cavity brick making machine

4 cavity Manual brick making machine:

4 cavity Manual brick making machine: A low cost, manual 4-cavity Brick Making Machines is used for smaller-scale brick making. Its easy-to-use manuals designs makes it simple and straightforward to operate. It is durable and makes four bricks at the same time, making more output. The entrepreneur or small businessman seeking make a local brick making may find this is a good equipment for him/her. This small-sized and flexible design allows the brick machine to function in different environments, leading to cheaper and environmentally friendly bricks production.

Specification of a manual brick making machine 4 Cavity

FEATURES | SPECIFICATION |

Capacity | 1600/2000 Pcs/Day |

Power Required | 0.78 Kw |

Usages | Manufacture Concrete Bricks |

Process | Manual |

Brick Size | 9 x 4 x 3 Inch |

Cavity | Four |

Single Cavity Interlocking Brick Making Machine

Interlocking single cavity brick making machine: the interlocking single-cavity brick making is a compact and effective solution for producing high-quality interlocking bricks. It moulds bricks with perfection, assuring uniformity and durability in every brick. Its user-friendly design offers increased productivity and reduces cost. Its single cavity design helps to create perfect interlocking bricks, making it the perfect choice for both small and medium-scale construction projects.

Specification of Single Cavity Interlocking Brick Making Machine

FEATURES | SPECIFICATION |

Capacity | 400 pcs / Day |

Power Required | Zero |

Usages | Manufacture Concrete/Clay Interlocking Block |

Process | Manual |

Block Size | 10 x 5 x 4 /5 Inch |

Cavity | Single |

Egg Laying Type Block Making Machine

Egg laying type block making machine: Egg laying type block making machine is very compact and economical but yields many different types of concrete blocks. With a special design that makes it portable, its movement is made simple and it can be placed in several construction points hence increasing the flexibility and convenience. The machine has simple controls to run and produces high quality blocks consistently.

Specification of Egg Laying Type Block Making Machine

860 L HYDRAULIC SPECIFICATION

FEATURE 860 L HYDRAULIC | SPECIFICATION 860 L HYDRAULIC |

Capacity | 4800 Blocks |

Method | Hydraulic Pressure |

Block Type | Hollow |

No. Of Operations | 50 – 60 per hour |

Vibro Motor 2 Nos | 2hp, 440v, 3ph |

Hydraulic Pump Motor | 5hp, 440v, 3ph |

Travel Motor | 0.5hp, 440v, 3ph |

Machine Weight | 1500kg (approx.) |

Power Required | 5 HP |

Cubic Space | 1700 x 1275 x 1700 MM |

400 X 200 X 200 mm | 4 Per Cycle |

400 X 200 X 150 mm | 5 Per Cycle |

400 X 200 X 100 mm | 8 Per Cycle |

400 X 200 X 100 MM | 0.5hp, 440v, 3ph |

Pavers Upto | 14 Per Cycle |

Semi Automatic Block/ Brick Making Machines

Semi-automatic brick/block making machine: It involves a semi-automatic semi-automatic brick/block making machine that makes bricks and blocks efficiently. Such system balances manual control with different automated functions to achieve uniformities of various kinds of bricks/blocks productions.

Specification of Semi Automatic Brick/Block Making Machine

FEATURES | SPECIFICATION |

Production Capacity | 3000 Block / Shift, 4000 Brick / Shift |

Power Pack | 7.5 HP (Three Phase) |

Maximum Pressure | 3000 PSI |

Hydraulic Tank | 230 Ltr |

Cavity | 2 for Block / 3 for Brick |

Mould Area | 450 x 450 mm |

Style Of Block can be made | Zigzag, Isec, bricks 9 x 4 x 3 inch |

Hydraulic Semi Automatic Brick Machine (Dhokla)

Hydraulic semi-automatic brick making machine: It is a hydraulic semi-automatic brick making machinery that helps make the brick manufacturing process efficient by combining both automation and hydraulic power. The hydraulic system also improves pressure and precision of operation. This is why the manufacturing process becomes effective. The semi-automatic nature of this machine balances out manual control while providing automated functions that are suitable for mid-scale builders in search of good quality bricks produced quickly.

Specification of Hydraulic Semi Automatic Brick Machine (Dhokla)

| FEATURES | SPECIFICATION |

| Production Capacity | 4000 – 4500/ Day |

| Power Required | 3 HP (3 Phase) |

| Usages | To make Pressurize Concrete Brick |

| Process | Hydraulic |

| Pressure | 3000 PSI |

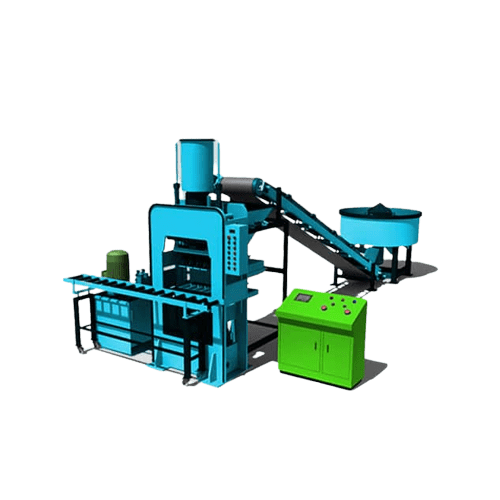

Automatic 4 cavity brick making machines

Automatic 4-cavity brick making is a completely new technology that makes it possible to produce up to four bricks per time. It means accuracy and speeds up the manufacturing process greatly. Such machine is characterized by streamlined automation processes that make it a good option for big construction ventures where uniform bricks of uncompromised quality are needed.

Specification of Automatic 4 cavity brick making machine

| FEATURE | SPECIFICATION |

| Production Capacity | 800 Blocks per hour / 1200 Bricks per hour |

| Cavity | Block 4 / Bricks 6 |

| Block Type | Solid, I shape, Zigzag |

| Method | Hydraulic Pressure |

| Power Requirement (machine+mixer+conveyor) | 15.5 KW 440v |

| Pressure | 3000 PSI |

| Belt Conveyor | 16ft |

| Pan Mixer 1 Number | 500Kg Capacity |

Usage and advantages of Brick Making Machines in Guwahati:

Enhanced Efficiency: The brick making machine simplifies the brick production process by cutting down on the time and labour involved in producing bricks, thus speeding up progress with regards to building of different projects such as apartments, business buildings, etc.

Versatility and Customization: These machineries can manufacture different size, shape, and specific bricks, allowing individuals or organisations involved in construction in Guwahati to build their desired structure as per their design specifics and necessities.

Consistent Quality and Structural Integrity: These machines are instrumental in the automatic production of bricks enabling consistency in quality and making an input on the structural integrity of buildings located within the city.

Cost-Effectiveness: These brick making machines enhance resourcefulness of resources and effectiveness of operation, resulting to significant savings in general construction, a factor that makes them economically practical options of undertaking constructions projects in Guwahati.

Sustainability and Environmentally Friendly Practices: Since fly ash is a by-product derived from the burning of coal our fly ash brick making machines were specifically designed for this purpose to promote sustainable and environmentally friendly construction methods which will help in preserving the environment around Guwahati.

Durability and Structural Resilience: The blocks that come out of our machines are stronger than any other block available in Indian market for use in construction. These blocks have excellent compressive strength and durability so that the buildings made of these bricks can stand for extended lengths of time through different environment challenges in Guwahati’

Key features of brick making machines in Guwahati:

Automated Operation: Brick making machines are almost always automated; in case of any necessity of manual work this reduces by a great extent to increase total productiveness.

Versatility: Capability to offer different brick types and dimensions for diverse construction uses and designs.

Durability and Strength: Facilitating the production of strong and long-lasting building materials such as hard bricks, which are suitable and effective for use in different construction work hence prolonging the lifespan of the buildings.

Energy Efficiency: Energy optimization is achieved by incorporating energy-efficient components and systems that consume less power, hence reducing overall expenses on operations.

Customization Options: Available in a range of configurable settings and configurations for specific projects, where one wants the bricks at a specific size or type.

User-Friendly Interface: Easy control interface, intuitive operation, and maintenance, designed for different level operator’s expertise.

High Production Capacity: Allow effective systems generating mass and hence respond to bulk construction work.

Material Utilization: Utilize raw materials effectively, waste management for cost effectiveness and green construction methods.

Interchangeable Molds: Ease in changing of moulds which facilitates production of varying bricks improves its variability & flexibility.

Safety Features: Featuring safety features that prevent possible accident occurrence for the operator while operating the machine.